What are our research interests?

Objectives

To control and understand the deposition and synthesis of thin solid films prepared by vacuum processes

To create knowledge and know-how on structuration of thin films at micro- and nanoscales

To develop original deposition processes for oriented and sculpted thin solid films

Description

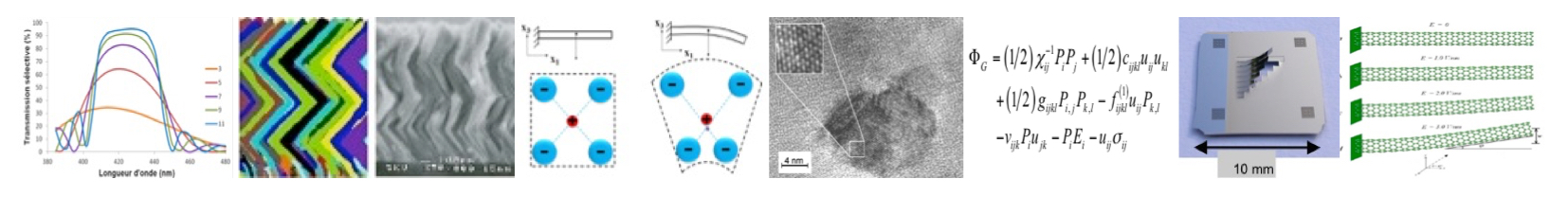

The main purpose of these activities is focused on the production of knowledge for the control and understanding of deposition and structuration processes on thin films. To this end, physical vapour deposition techniques, especially sputtering, are mostly involved. The development of new and original sputtering methods is investigated for the synthesis of metallic and ceramic coatings. For the non reactive sputtering mode, a strong emphasis is put on an innovative approach: the “GLAD” technique (GLancing Angle Deposition). Such a technique uses an oblique incident angle of the sputtered particles during the growth of the film on the substrate. This latter (commonly on silicon to prepare MEMS, actuators or sensors) can be fixed or rotating. Some patterned surfaces (dots or seeds organized according to lattices) can be prepared by e-beam of lithography prior the application of the deposition of structured films by GLAD. This GLAD technique (poorly explored deposition method, especially in Europe) appears as an attractive way to produce various architectures like inclined columnar structures, zigzags, spirals, … In addition, this technique is not restricted to the deposition of metals, but can also be applied to ceramic compounds. This type of compounds is also of special interest due to their optical, mechanical and electronic performances. However, ceramic thin films often require the reactive sputtering mode. Since non linear effects are systematically observed when reactive gases like oxygen and/or nitrogen are used, some improvements of the reactive process are developed like the Reactive Gas Pulsing Process (RGPP). In addition, mecanosynthesis is carried out to prepare nanostructured powders in order to make targets for sputtering.

Keywords

Sputtering, nanostructuration (powders or films), oriented growth, reactive gas pulsing process (RGPP), nanocomposites, multilayers, nanoparticles

Studied materials

Metals and alloys : Ti, Ta, Nb, Cr, Fe, Al, TiAl, TiNi, Ni2MnGa

Oxides : TiOx, CrOx, FeOx

Nitrides : TiN, AlN, TaN, FeN, TiAlN

Oxinitrides : TiON, FeON,

Others : TaCN, TaCON