In peer reviews for the 5 last years

Objectives

Understand the growth mechanism of thin films

Model wear through multi-scale and multi-physics simulations

Predict the physical properties of materials and thin films

Compute the light diffusion peculiar to nanostructures in order to characterize them

Find behavior laws for these materials

Description

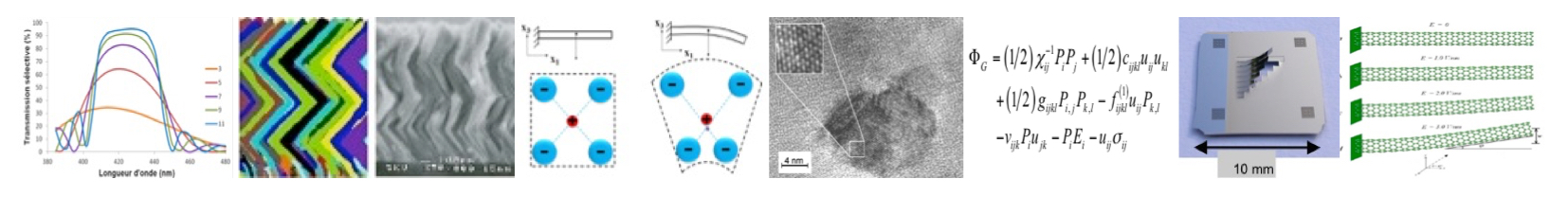

Work in this area is focused on the development of tools to model the deposition processes of thin films, tools to simulate the multi-physics characteristics of this kind of materials, tools to study the formation and the agglomeration of wear nanoparticles, as well as tools for the multi-physics simulation of carbonaceous nanomaterials. This is basically done in order to find and understand laws for the behavior of these functional materials under various physical excitations, to predict the optimal parameters for their elaboration or their optical properties.

Indeed, the physical and mechanical properties of the thin films used in Microsystems depend very strongly on the details of the elaboration processes. It is thus required to quantify the characteristic sizes on which the operation of these Microsystems depends as well as predict their reliability and their mechanisms of degradation.

In order to study the growth of a thin layer, a Monte Carlo code has been developed. This code uses a Volmer-Weber type of model for growth complemented with the density and the organization of the nucleation sites, and incorporates surface diffusion and various possible interactions between the sputtered particles. Thanks to such a tool, it is possible to predict the structural characteristics of films having a column-like structure at micrometric and nanometric scales. Moreover, the code makes it possible to understand the orientation and the architecture of the columnar structures obtained when these thin layers are deposited under oblique incidence and on mobile substrate (in direct relationship with the GLAD technique - Glancing Angle Deposition – developed in topic I).

The understanding of the physical, mechanical and tribological properties of materials and surfaces is generally possible thanks to the development of analytical or numerical models describing the interactions between the experimental probe and the material tested. However, these interactions are often complex, so that it is often necessary to use identification methods based on extensive 2D or 3D simulations using finite or discrete elements or Green’s “functions” techniques. For example, this is the case for nanoindentation tests if one wants to quantify all the data related to these tests for bulk materials as well as thin films, e.g. their elastic and inelastic behavior or the degree of apparent isotropy. This is also true in the case of Microsystems with active films (piezoelectric, ferroelectric, SMA, magnetic SMA.) or in the case of light scattering by nanostructures. Indeed, in this later case, certain scattering characteristics seem to be very sensitive to chemical inhomogeneities of the scatter, even when they have a sub-wavelength characteristic size.

In the future, we intend to mix continuum media approaches with atomic or molecular scale simulations in order to achieve multi-scales and multi-physics simulations.

Keywords

Modeling, Monte Carlo, molecular dynamics, response functions and interaction tensors, simulation of growth processes, reactive sputtering, scattering, multi-physics behavior laws, identification of parameters, numerical simulations of nanoindentation test conditions.

Numerical tools

Finite elements, Monte Carlo, Molecular Dynamics or DDA (dipole-dipole approximation) codes