Microsystems and sensors for energy

We design thermal and/or fluidic microsystems, and integrated thermal sensors that can be produced by collective microfabrication (MIMENTO facilities). Our systems and sensors are designed to quantify, manage and convert energy.

To this end, we have developed specific test benches for phenomenological analysis in our micro and macrosystems: physical problems on the millimeter and sub-millimeter scales (similarity and scaling law, disparities/mismatch, thermalization and friction losses), alternating vs. continuous flows (impact of physical parameters on the friction factor), or liquid/vapor state change (quantification of dynamics and heat exchange at local level).

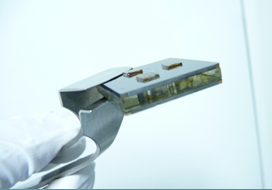

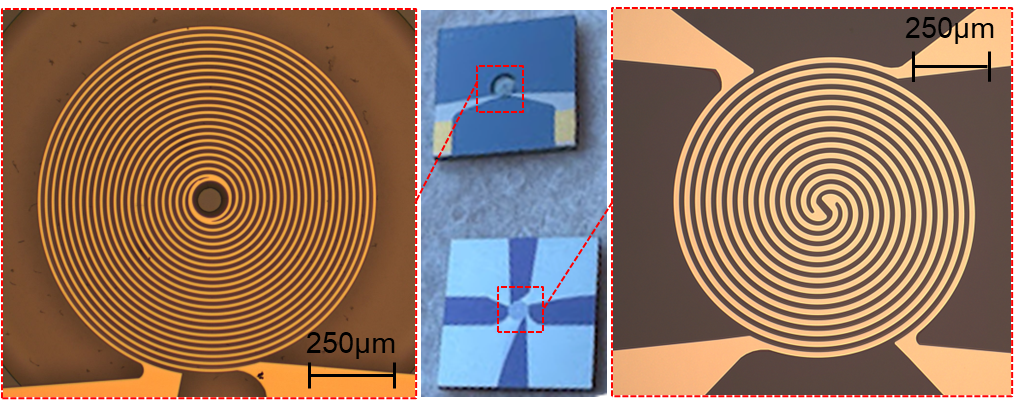

The first topic concerns the development of a Stirling micro-engine for low temperature thermal energy harvesting (ANR MISTIC 2013 - 2016; Region Bourgogne Franche Comté STIP'MEMS 2015-2018). This is a collaborative project between two Femto-st departments (MN2S & Energy) and two academic partners (Symme laboratory, Savoie Mont Blanc Univ. & UMI-LN2, Sherbrooke Univ.). The Stirling engine is based on a reversible cycle of compression and isothermal expansion of a gas that allows to convert thermal energy into mechanical energy, or the reverse (to convert mechanical energy into thermal one). A miniaturized Stirling engine demonstrator (based on a vertical stack of wafers) has been realized using microfabrication technologies.

Microfabricated micro-Stirling engine

(3 engines in series) - Thèse A. Diallo

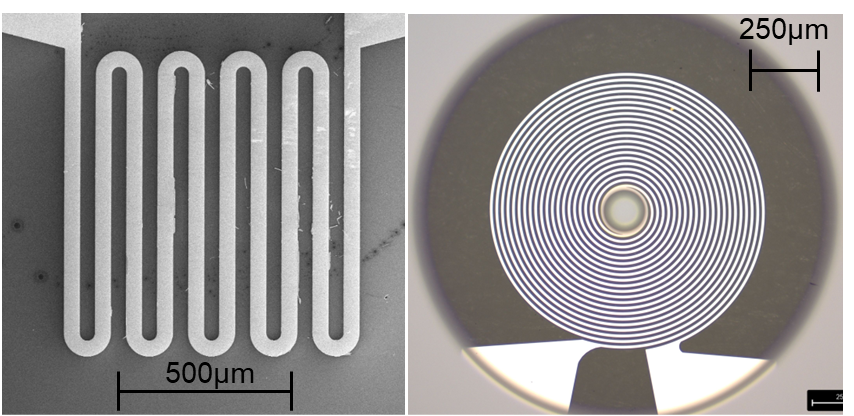

Integrated Heat flux sensor on the nucleation surface (L/V phase change)

The second topic concerns the phenomenological analysis of flow in microchannels (similitude & scales law, thermalization and friction losses…) (EUR-EIPI/I-Site). The change of scale (for instance, in the micro-Stirling engine) raised mechanical, fluidic and thermal issues that must be overcome.

The fluidic optimization of microsystems and the limitation of the hydraulic resistance to flow is a key point for many applications in micro-fluidics :

- Permanent flows in microchannels benefit from numerous studies but with results that can be contradictory depending on important parameters not always taken into account (roughness, aspect ratio, compressibility...). .

- Alternating flows (mean zero displacement velocity) have very little documentation at micrometer scales. A good knowledge of the influence of parameters such as geometry, roughness, singularities, etc. is necessary for the optimization of microsystems, in particular with the application to the Stirling type micro-engine.

Energy harvesting, conversion, flow and thermal analysis requires the development of metrological means and/or sensors integrated into the micro-manufacturing process adapted to the studied geometry.

Temperature sensor (RTD)

Contacts :

Magali Barthès (magali.barthes@femto-st.fr)

TraThI

Thanks to a multi-scale approach, the TraThI project aims at a better understanding of the transfer mechanisms at the interfaces in order to propose new heat extraction techniques, able to respond to such power density levels. The approaches will be experimental, numerical and theoretical, bringing together partners with complementary skills (thermal, two-phase flows, surface treatment, micro-fabrication, micro-sensors).