Non contact robotics is as a promising solution to handle objects of less than 500 micrometers. Due to the small scale, on board actuation or sensing is not possible. Remote actuation, using for example magnetic fields, enables to power these microrobots. Several actuation principles can be used depending on the properties of the objects that should be controlled. However, major challenges, such as the closed loop control of 3D trajectories or the integration of manipulation tools, must still be faced to perform advanced tasks.

Compared to classical approaches where the tools plus the objects should be moved, the use of remote force fields enables moving only the object. At small scales the inertia of the objects decreases drastically, which leads to important accelerations. My research activities focus on exploiting this property to increase the velocity of the displacements of the objects, while maintaining a good precision of the trajectory control. Several challenges must be faced on different topics:

- Modeling: accurate models of the system that can be inverted in real time to perform trajectory control must be defined.

- Design: the actuation platforms must be designed to maximize the force applied on the objects, which introduces important non linearity.

- Fabrication: micrometer size robots must be fabricated in clean room facilities.

- Sensors: high frequency position feedback of the objects is necessary, which can necessitate the use of original position sensors.

- Control: control laws robust to the perturbation must be implemented at high frequency.

Magnetic actuation platform

Magnetic actuation platform

Magnetic actuation

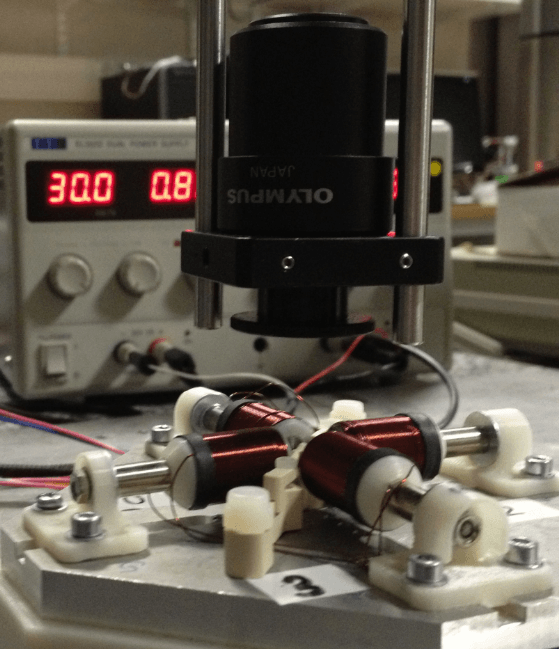

Magnetic actuation platforms are composed of several coils used to produce a magnetic field. The magnetic field gradient induces a force. Ferromagnetic objects are attracted toward the highest magnetic field gradients. By controlling the current inside the coils it is possible to control the trajectory of the objects. A camera monitors the position of the object in its environment in real time.

Most of the works on the state of the art focuses on actuation inside liquids. However the viscosity of the liquid induces a drag force which decreases the velocity that can be reached. I study actuation in different environments, such as in air or at the interface between air and liquid to increase the velocity of the displacements.

Magnetic actuation in air

Precision is still a challenge for actuation in air. Surface forces are predominant compared to volume ones. Overcoming adhesion between the substrate and the microobobject is thus a challenge. Several directions have been investigated, among which the use of piezoelectric actuation to induce a vertical movement of the object; the structuration of the substrate using microfabrication techniques and the use of the magnetic torque to overcome adhesion. In addition control laws taking into account the two available inputs, the intensity of the current inside the coils and the duration of this signal have been proposed.

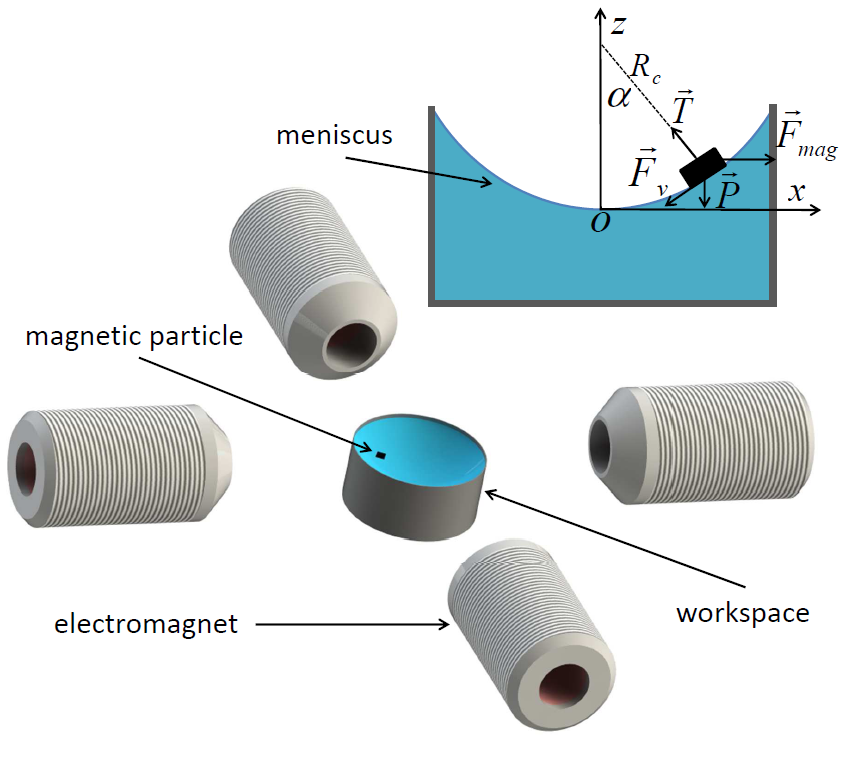

Magnetic actuation at the interface between air and liquid

To avoid adhesion issues we have investigated magnetic actuation of objects placed at the interface between a liquid and air. Due to surface tension the objects are placed on the surface, without being immerged. The velocity is not restrained by the viscosity of water. This approach arise original problematics due to the presence of a meniscus and to the high velocities that are reached. Specific control laws must be implemented to ensure high speed trajectory tracking despite the non-linearity of the force fields. Modeling and control have been investigated and tested experimentally. Velocities up to 6mm/s have been reached for objects of less than 100 µm.

Laser based actuation

Lasers are attractive tools in the framework of non contact micromanipulation. Two different properties are exploited by microrobotic systems: the generated optical forces and the generated heat. The works presented here exploit the generated heat either to move particles.

Actuation based on thermocapillary convective flows

Actuation based on thermocapillary convective flows

Non contact actuation based on thermocapillary convection flows

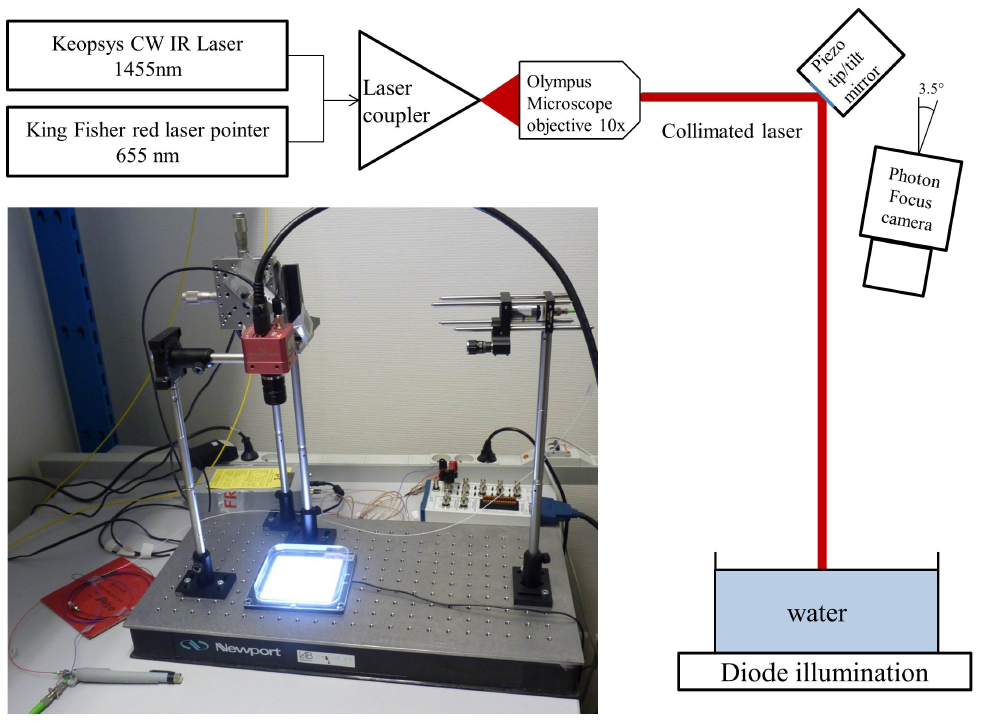

Thermocapillary convection is a promising principle to manipulate particles at the fluid/gas interface. Compared with approaches based on natural and Marangoni convections, our approach uses thermocapillary convection generated by a laser heating the fluid from the top and not from the bottom. This has several advantages, the most relevant being that it does not depend on an hydrodynamic instability to onset the flow motion. Laser heating creates large localized thermal gradients that make the flow velocity fast and localized. Simulations show that flow velocities up to 8.5 mm/s can be obtained using as little power as 38 mW with a temperature increase as little as 4 °C. As a proof of concept, steel spherical particles 20 of 500 μ m diameter are successfully displaced using this principle, which attain a mean maximal speed up to 4 mm/s. Also, 1000-μm-diameter steel spherical particles are displaced along a given trajectory using a manual control. These first results demonstrate the high potential of this new approach based on thermocapillary convection for controlled noncontact actuation at high speeds at microscale. Closed loop control of a single particle has been demonstrated using different actuation strategies, either using point based actuation or using ligh patterns. The manipulation of a particle in presence of an obstacle has also been demonstrated. This works is conducted in collaboration with ULB in Belgium.

Contact

Aude Bolopion

Involved people

Current people: Franco Pinan Basualdo (ULB, Belgium)

Former people: Soukeyna Bouchebout (ISIR, France), Mohamed Dkhil, Ronald Terrazas Mallea (ULB, Belgium)